Boosting Polymer Magnets: The Power of Surface Treatments

Boosting Polymer Magnets: The Power of Surface Treatments

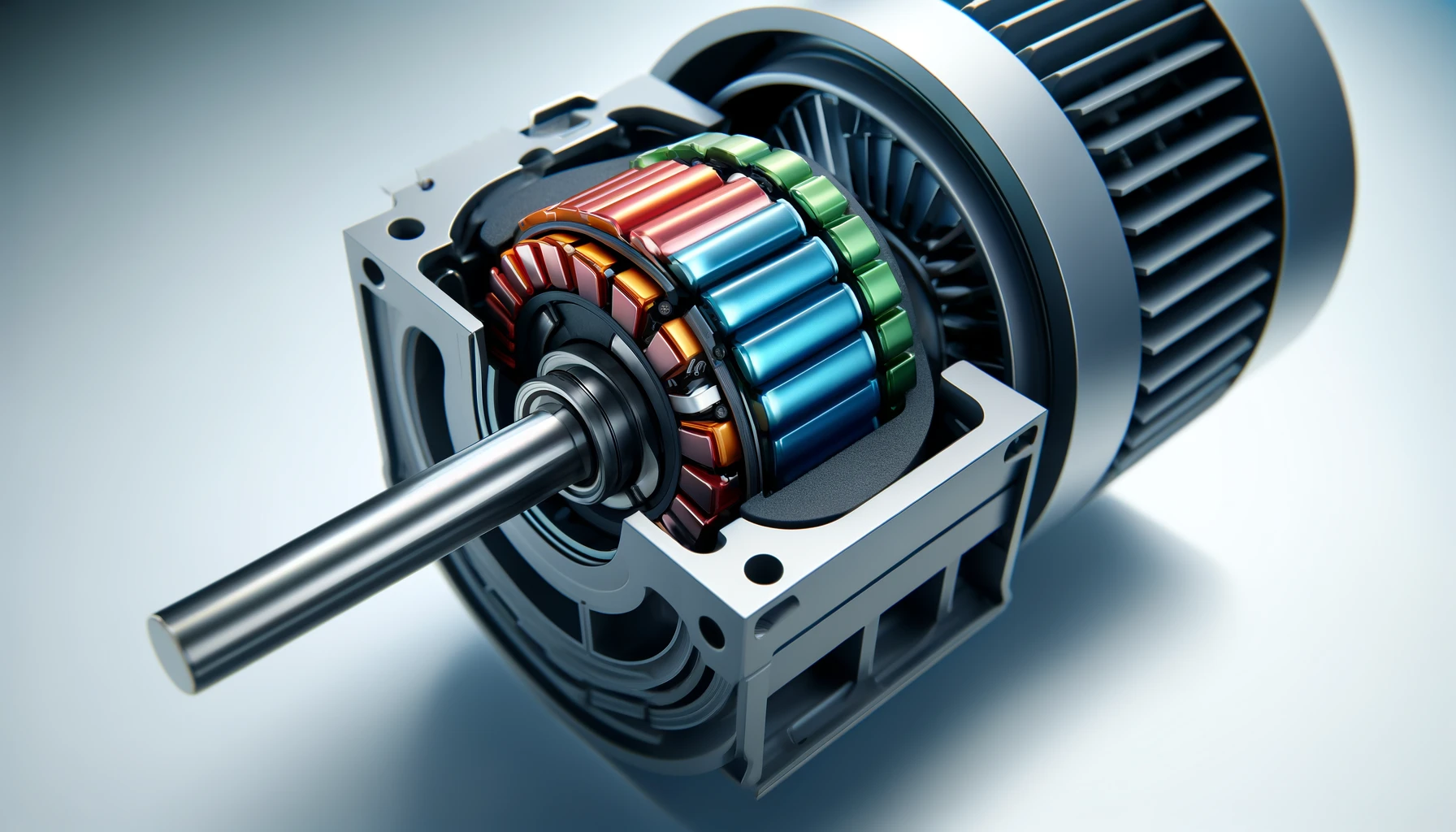

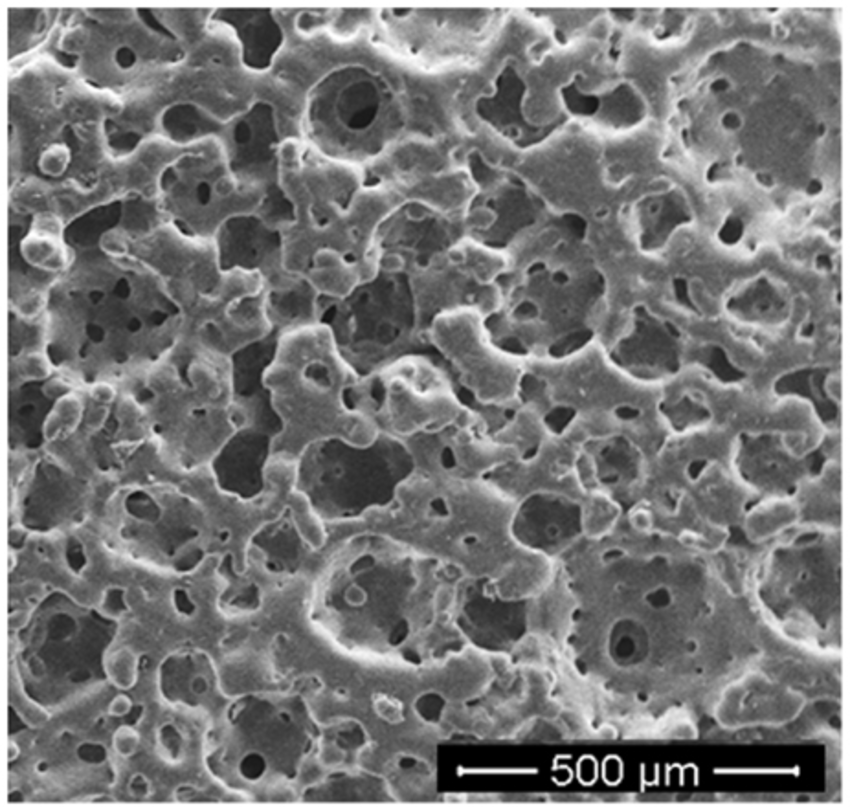

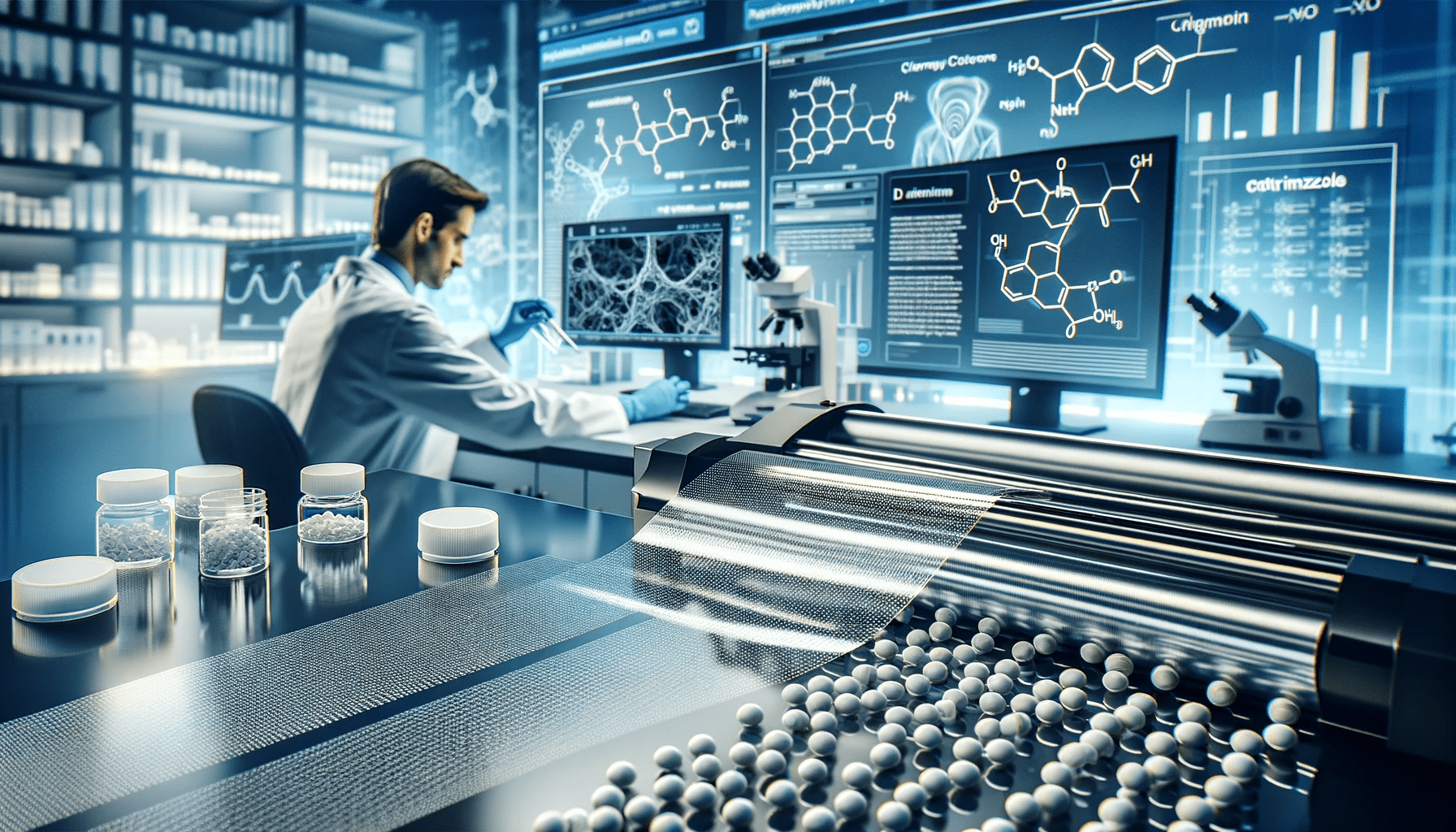

Researchers have innovated polymer-bonded magnets, essential for their design flexibility and cost efficiency, by improving their heat resistance and magnetic capacity. By fine-tuning the surface treatment of magnetic particles and utilizing advanced polymers like poly(phenylene sulfide) (PPS), they’ve achieved a notable increase in performance. The use of silane coupling agents allows for a higher magnetic particle concentration, enhancing the magnets’ strength without compromising workability. This breakthrough extends the application range of these magnets, presenting a durable, high-performance material option for industries requiring reliable magnetic solutions.

Please subscribe to access the full article download.

For more information or if you have any questions, please contact the author.