Advancing Foam Polyimides: New Innovations in Composites

Advancing Foam Polyimides: New Innovations in Composites

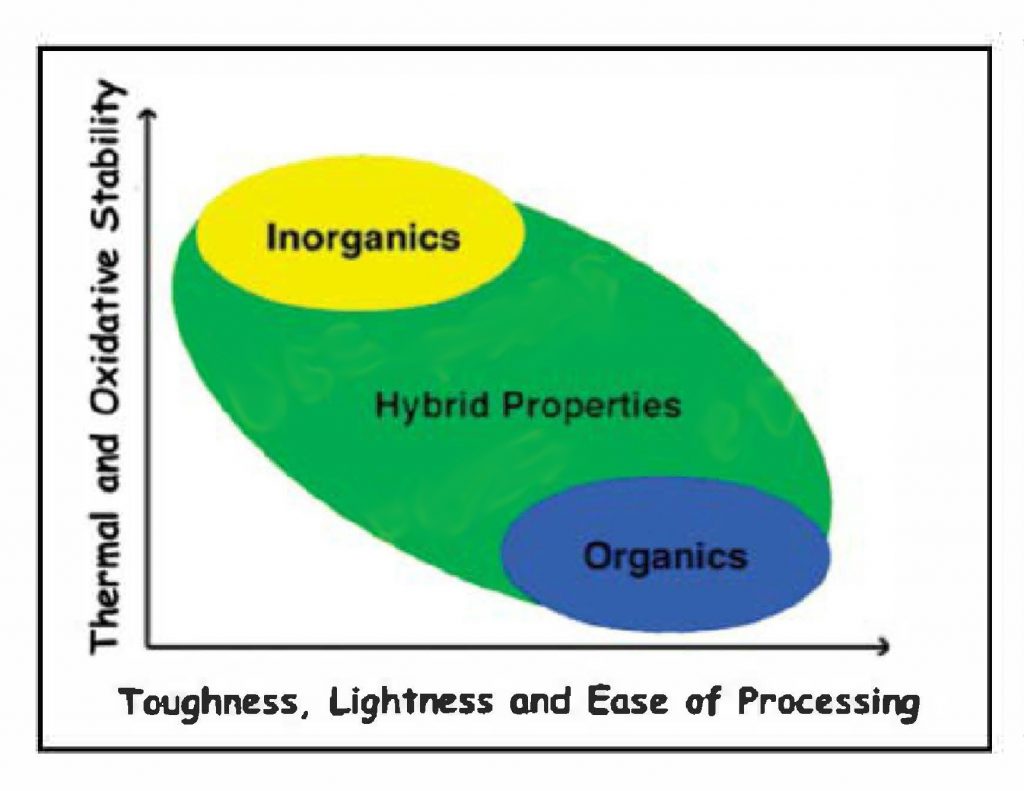

Discover how changing the chemical composition of foam polyimide prepolymers can significantly enhance their properties! Researchers found that modifying components like diamines and dialkyl esters improved the processing and strength of foam polyimide composites. These lightweight, durable materials offer superior thermal and vibration insulation, making them ideal for aerospace, automotive, and medical applications. By understanding and optimizing these chemical changes, we can create composites that combine the benefits of load-bearing fiber materials with the insulating properties of foam.

Please subscribe to access the full article download.

For more information or if you have any questions, please contact the author.