Atomise Polymers to Maximise Profits

The difficulties of mass-producing micron-sized high-quality powders from molten polymers can be avoided by using high pressure gas atomisation methods.

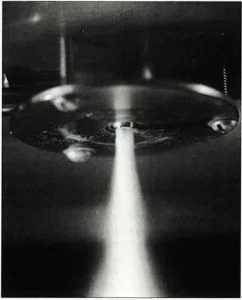

The production of micron-sized polymer powders from molten polymers is an attractive, facile, low energy, and economic process. Polymer powders with tailored characteristics such as particle shape and size distribution, and purity can be directly prepared from the molten state of polymers such as polyethylene-based waxes that cannot be ground using conventional grinding methods. The gas atomisation process (GAP) for mass-producing high quality spherical polymer powders involves the use of high pressure (approximately 7.6MNm-2 maximum) nitrogen gas and a specifically designed nozzle to atomise a molten stream of polymer into fine droplets which cool to form spherical powders, Powders with properties tailored to varying applications can be efficiently produced in short cycle times by changing few process control variables in a contamination-free environment, thus making the GAP a useful alternative to conventional grinding processes. These benefits of the process together with its flexibility, high throughput and facile nature can be expected to make it highly attractive to industrial processes that must be capable of mass production, safe and environmentally benign operation.

Patents

Atomizing apparatus for making polymer and metal powders and whiskers

Apparatus for and method of producing monodisperse submicron polymer powders from solution

Method of making polymer powders and whiskers as well as particulate products of the method and atomizing apparatus

For more information or if you have any questions, please contact the author.